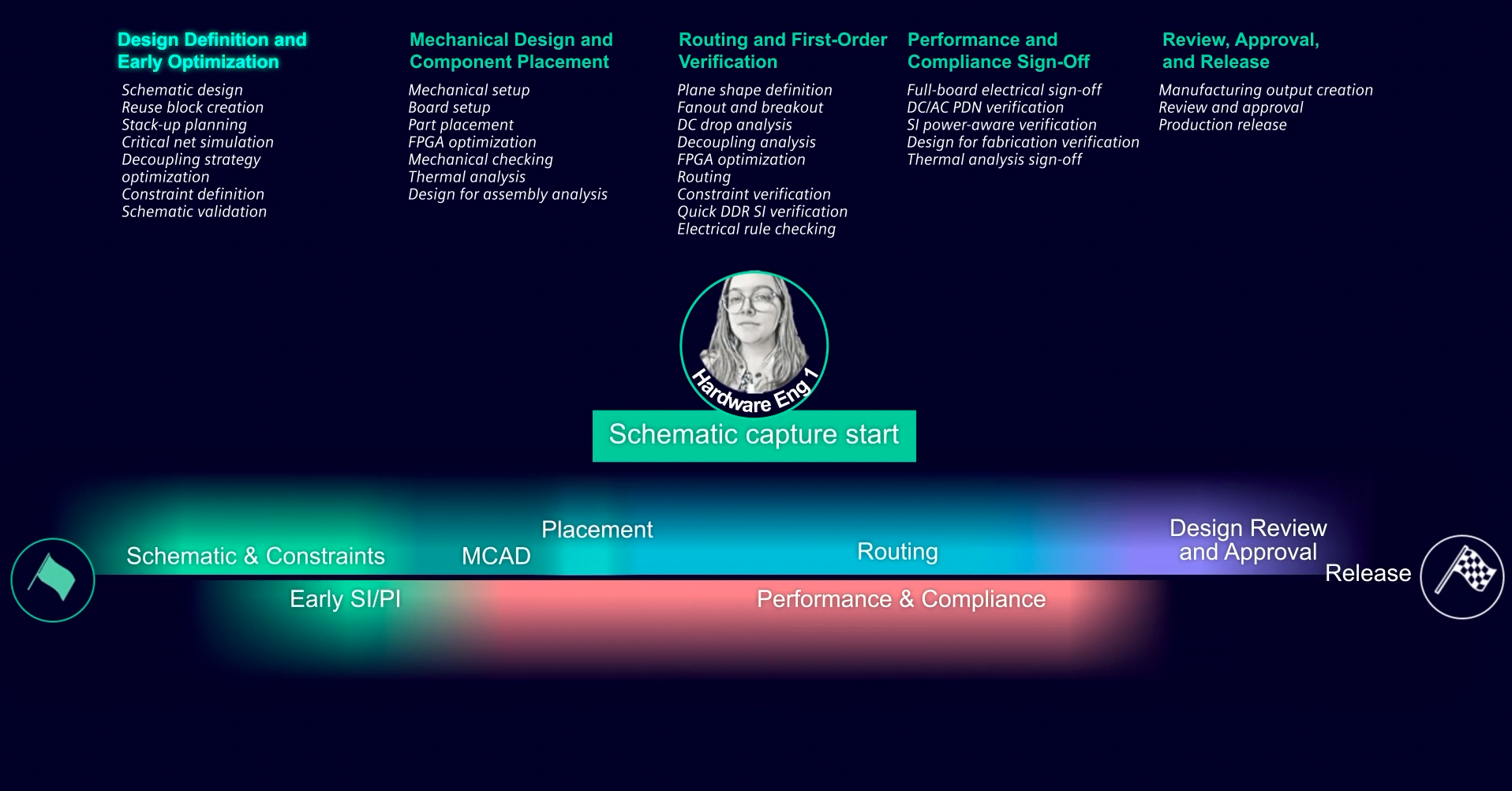

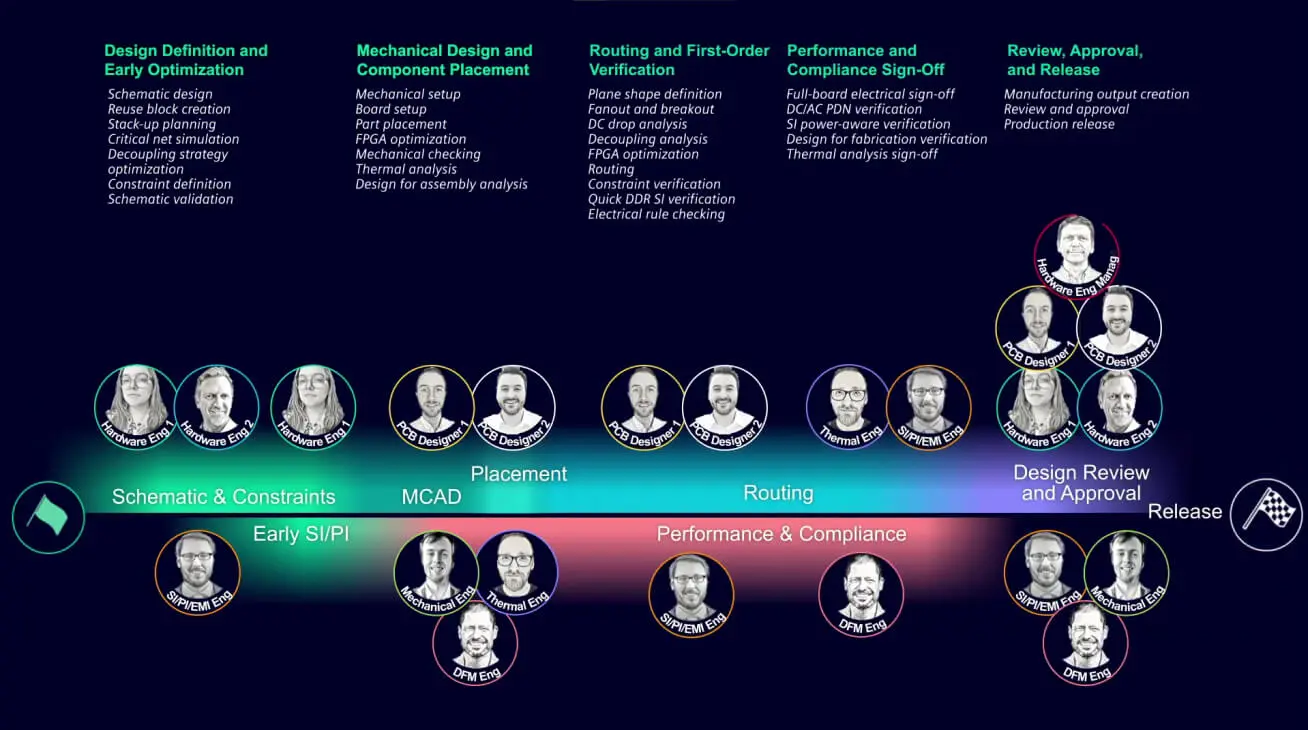

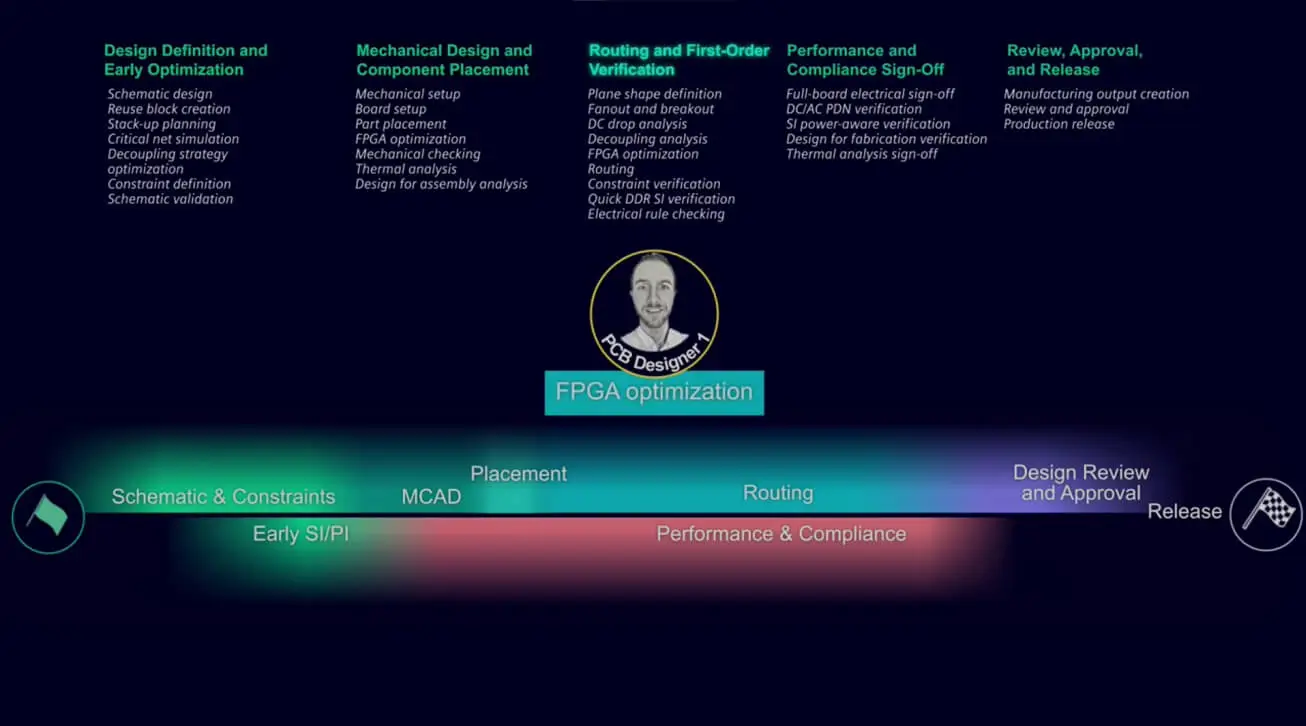

Design concurrently

Engineering teams can work concurrently throughout the product development process to reduce design cycle time and improve product quality.

Define intent

Quickly capture your schematic, leveraging design reuse and system hierarchy. Define stack-up and design constraints to ensure the system works as intended.

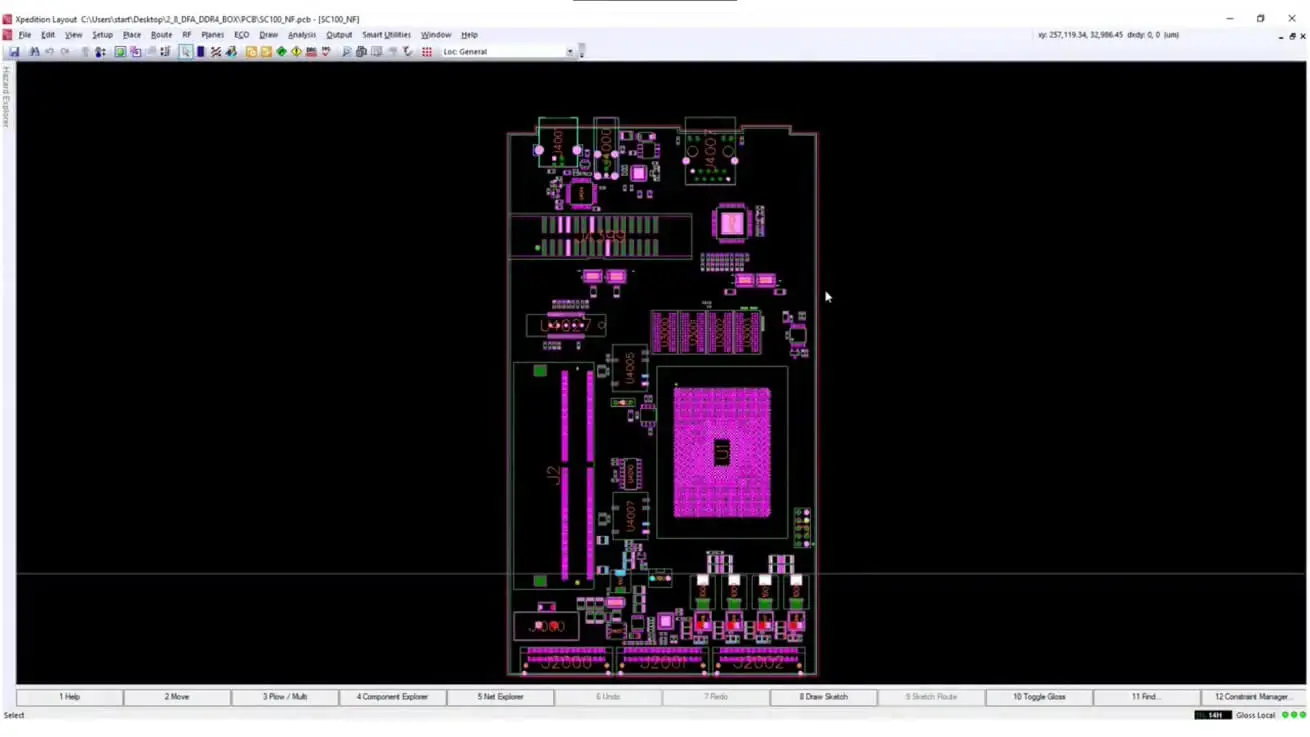

Automate layout

Leverage correct-by-design automation concurrently with your team to accelerate constrained high-speed designs.

Optimize across multiple domains

Efficient, secure, concurrent design across all engineering teams to optimize project costs, accelerate design time, manage data integrity, and improve quality of results.

Collaborate between ECAD & MCAD efficiently

Optimize electronics designs within tight form-factor constraints while still meeting quality, reliability, and performance requirements.

Co-design FPGA & PCB

Bridge the FPGA and PCB design domains for automated, fast, and error-free bi-directional data exchange that reduces PCB layer count, product cost, and design time.

Design products that work

Verify during the design process to achieve first-pass success while optimizing products for performance and manufacturability.

Verify often

Integrated and easy to use verification tools enable engineers to check a design early and often, ensuring first-pass success.

Ensure manufacturability

Assembly analysis on the fully placed and optimized board ensures that the part placement will work for production.

Define a MBSE strategy

From system requirements to implementation and manufacturing, Xpedition Enterprise creates aa model-based approach allows team members to view of the entire system (electronic, electrical, mechanical, and software) and models pieces of that system, while defining and optimizing interconnectivity and traceability from one domain to the other.

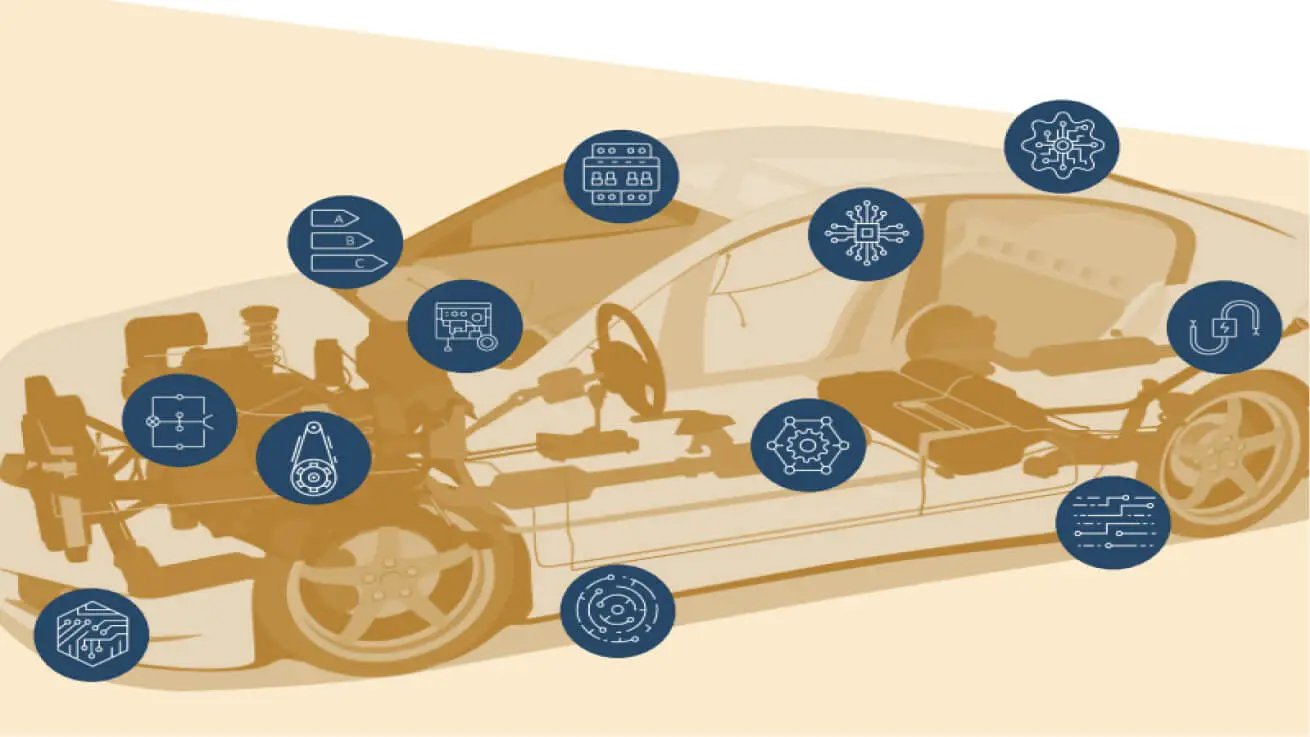

Develop integrated systems

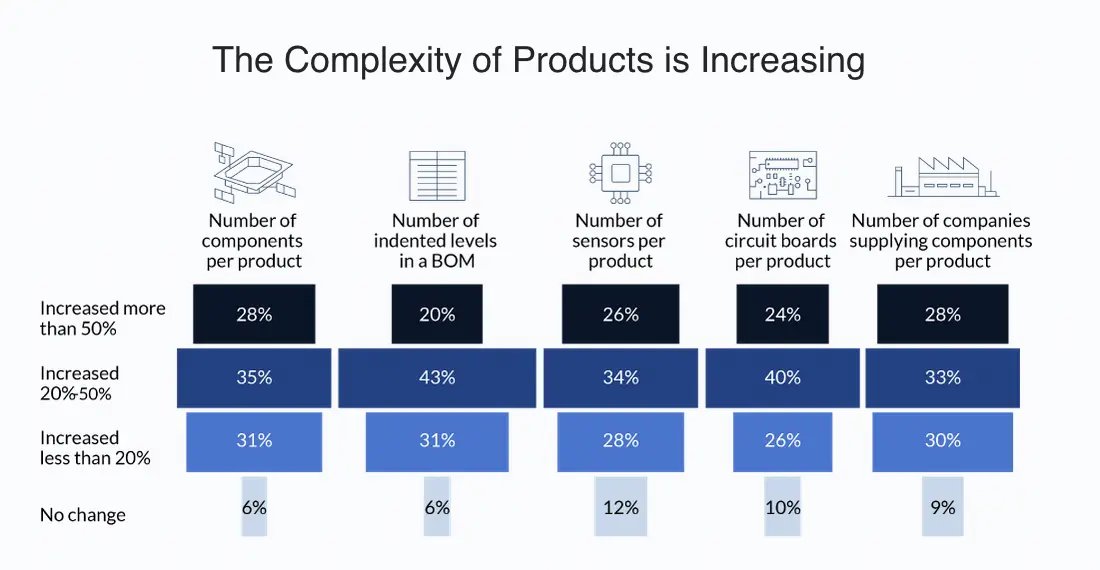

Early use of simulation, both mechanics and electronics, combined with model-based systems engineering (MBSE) assist manufacturers in navigating the changes caused by the increasing complexity of electronics design and the organizational processes that come from it.

Leverage models to shift-left

Apply a shift-left strategy, involving the implementation of new methods to ensure system integration, boost design reuse, and employ digital prototyping during the design and verification phases of development.

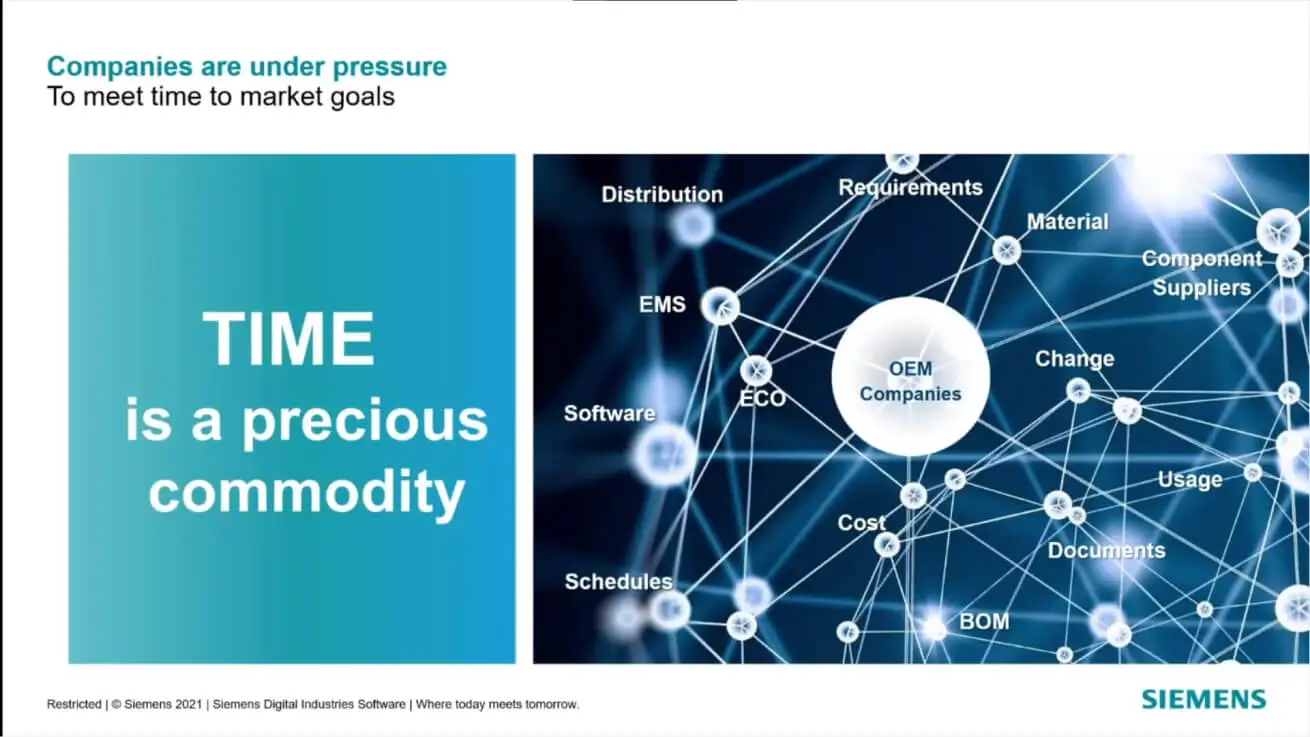

Digitalize the supply chain

Digitally transforming how the electronics value chain is traversed will unlock the full innovative potential of system design companies all over the world. With Siemens, companies can optimize not only their systems design process but also every link to all the stakeholders in the value chain, achieving higher levels of digitalization and profitability.

Make smarter decisions, earlier

Never design in another obsolete part. Empower engineers with real-time component sourcing data to make more informed part decisions without ever leaving the schematic. Prioritize the component vendors you use and mitigate the risk of component decisions early in the design process, saving you time and money.

Markus Välkky, Nokia

Bastian Diehm, TESAT